Servoelectric Energy Consumption

Servoelectric Energy Consumption

Servoelectric Energy Consumption

During Operation and at Idle

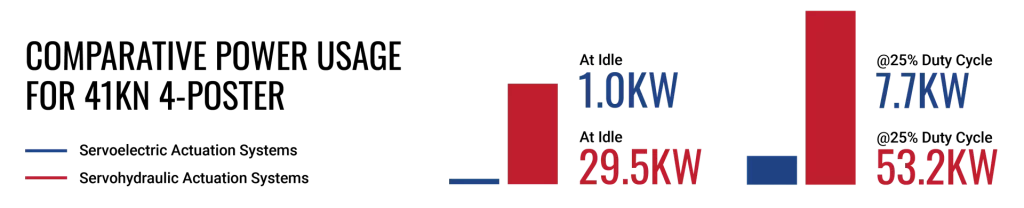

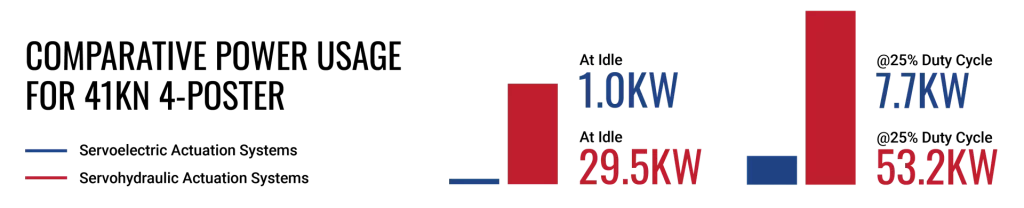

SEA systems demonstrate an advantage in energy efficiency over their servohydraulic counterparts. During a typical operation cycle with a 25% duty cycle, SEA systems consume significantly less energy, with a total power requirement of 7.7kW compared to the 53.2kW required by servohydraulic systems. Even at idle, SEA systems require only 1.0kW of power compared to the 29.5kW needed by hydraulic systems. This efficiency translates into a dramatic reduction in energy costs, with SEA systems operating at less than 20% of the energy cost of comparable hydraulic systems.

During Operation and at Idle

SEA systems demonstrate an advantage in energy efficiency over their servohydraulic counterparts. During a typical operation cycle with a 25% duty cycle, SEA systems consume significantly less energy, with a total power requirement of 7.7kW compared to the 53.2kW required by servohydraulic systems. Even at idle, SEA systems require only 1.0kW of power compared to the 29.5kW needed by hydraulic systems. This efficiency translates into a dramatic reduction in energy costs, with SEA systems operating at less than 20% of the energy cost of comparable hydraulic systems.

Energy Efficiency of Servoelectric Systems

The move towards servoelectric systems represents a major step forward in enhancing energy efficiency and sustainability in industrial testing and manufacturing sectors. Utilizing the built-in benefits of servoelectric technology, including lower energy use, the ability to reuse energy, and decreased heat output, industries can attain higher operational effectiveness and reduce their environmental impact.

Maintenance and Reliability: A Paradigm Shift

SEA systems significantly reduce maintenance needs and operational costs through streamlined design and fewer moving parts, eliminating common issues like fluid leaks and component wear seen in hydraulic systems. The absence of hydraulic fluid and oil reservoirs simplifies maintenance, while the durability of electric motors and modular design minimizes downtime and spare parts costs. Additionally, replacing servoelectric components is more cost-effective than the extensive servicing required for hydraulic systems.

The Principle of Regenerative Energy in Servoelectric Systems

These systems leverage bidirectional motor operation, allowing them to both drive loads and act as generators. During braking or deceleration phases, these motors reverse their function, generating electrical currents that push energy back through the system. This regenerative capability enables the conversion of kinetic energy into electrical energy, which can be redirected for various purposes. The regenerated energy can be routed back into the system, offsetting energy consumption, or the regenerated energy can be routed back into the grid.

Reduced Heat Generation

SEA systems generate significantly less heat due to the conversion of electrical to mechanical energy. Additionally, this decrease enhances the operational efficiency and safety of the system while also contributes to lower cooling requirements, further reducing energy consumption and operational costs.

Energy Efficiency of Servoelectric Systems

The move towards servoelectric systems represents a major step forward in enhancing energy efficiency and sustainability in industrial testing and manufacturing sectors. Utilizing the built-in benefits of servoelectric technology, including lower energy use, the ability to reuse energy, and decreased heat output, industries can attain higher operational effectiveness and reduce their environmental impact.

The Principle of Regenerative Energy in Servoelectric Systems

These systems leverage bidirectional motor operation, allowing them to both drive loads and act as generators. During braking or deceleration phases, these motors reverse their function, generating electrical currents that push energy back through the system. This regenerative capability enables the conversion of kinetic energy into electrical energy, which can be redirected for various purposes. The regenerated energy can be routed back into the system, offsetting energy consumption, or the regenerated energy can be routed back into the grid.

Reduced Heat Generation

SEA systems generate significantly less heat due to the conversion of electrical to mechanical energy. Additionally, this decrease enhances the operational efficiency and safety of the system while also contributes to lower cooling requirements, further reducing energy consumption and operational costs.

Maintenance and Reliability: A Paradigm Shift

SEA systems significantly reduce maintenance needs and operational costs through streamlined design and fewer moving parts, eliminating common issues like fluid leaks and component wear seen in hydraulic systems. The absence of hydraulic fluid and oil reservoirs simplifies maintenance, while the durability of electric motors and modular design minimizes downtime and spare parts costs. Additionally, replacing servoelectric components is more cost-effective than the extensive servicing required for hydraulic systems.