Product - Load Frames

Damper Testing

Damper testing assesses the performance, durability and service life of essential automotive components, including shock absorbers, dampers, struts and more

Applications for Damper Testing

- Durability

- Accelerated Life

- End-of-Line Production

- Research & Development

eMpulse Damper Test Systems

eMpulse series of SEA-based damper test systems bring state-of-the-art technology to automotive damper testing. Our damper testers include two standard models offering varying peak dynamic force capacities (SEA.10.200 – 10.3kN (2,328lbf); SEA 20.200 – 20.7kN (4,652lbf)), and achieve significantly higher continuous loads, making them the only electric option for extended durability testing.

Standard and custom configurations are available for various applications, including:

- Damper characteristics

- Strut/shock testing

- Spring testing

- NVH component testing

- Full spectrum of waveform

- Road profile/time history playback

- High velocity configuration

Control System

eMpulse damper test systems come with Microsoft Windows®-based DAMPER TEST control and analysis software on a TIAB Controller, which generates a full spectrum of waveforms, including sinusoidal, triangle, square, random, frequency sweeps and other custom waveforms. The software also allows road profiles and time history data to be imported and replayed. Our SEA systems take advantage of fully integrated digital processing, without introducing electrical noise inherent in analogue conversion processes, providing more precise control as well as more comprehensive troubleshooting, diagnostic and monitoring tools.

Advantages of SEA Damper Test Systems

Designed to replace servo hydraulic-based systems and exceed the performance of other electric options; servo-electric actuator (SEA)-based damper testing systems offer a clean, efficient and dynamically responsive solution for both performance and durability testing in the automotive industry.

The key benefits of SEA damper test systems technology include:

- Energy efficiency

- Quiet operation

- Full digital control with built-in diagnostics

- High continuous dynamic force capacity

- High bandwidths

- Liquid or air-cooling

- Multiple measurements, control algorithms and configurable

Inputs/Outputs

Damper Test Functionality

Damper Test Functionality:

- Gas Force Measurement

- Stiction Measurement

- Force vs. Velocity

- Force vs. Displacement

- Multi-point Force vs. Velocity (PVP)

- Temperature or Time-based precycles

- Customizable test steps

- Data logging and analysis

- Configurable user inputs & output

Damper Technical Details

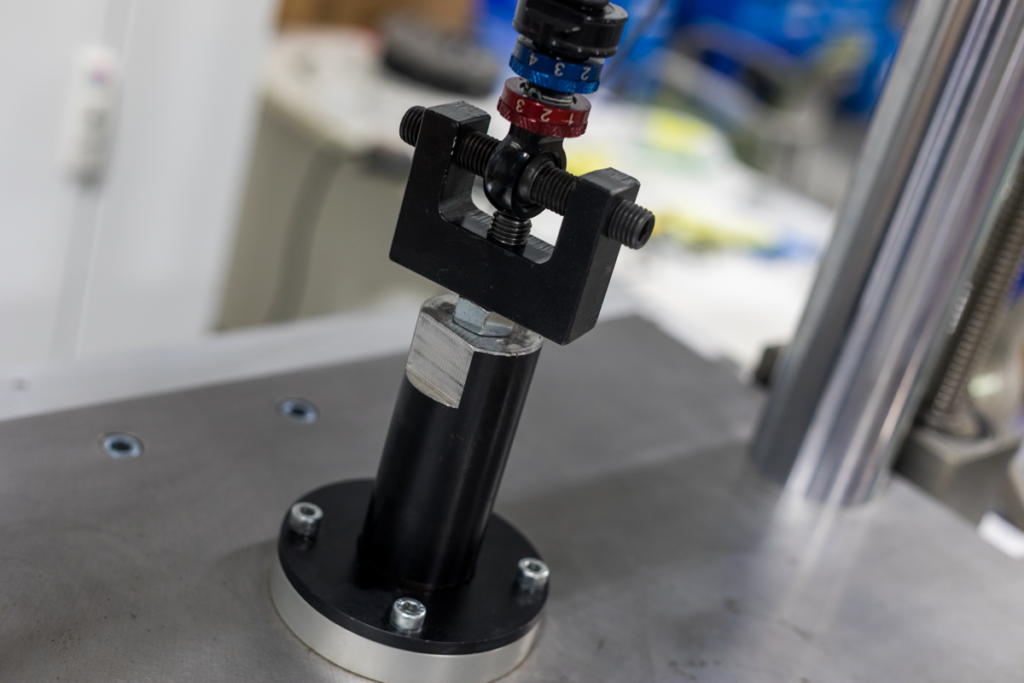

A Damper system consists of a few major components. These subsystems include the Servo Electric Actuator Assembly (SEA), Columns and Crosshead assembly with optional automatic lifts and locks, optional Interlocked Safety Cage, Main Electrical Cabinet, and Servo Control Workstation.

eMpulse offer solutions for both Production line use and Research and Development. While both Production and R&D Damper Test Software are available, the use of these two software packages is exclusive: Only one instance of each software can be operated at a time. Once either software package is closed, either one can then be opened for normal operation.

- Servo Electric Actuator Assembly

- Columns and Crosshead Assembly

- Main Electrical Cabinet

- Servo Control Workstation