Electrodynamic Shaker Refurbishment and Repair

Electrodynamic Shaker Refurbishment and Repair

Refurbishments and Service

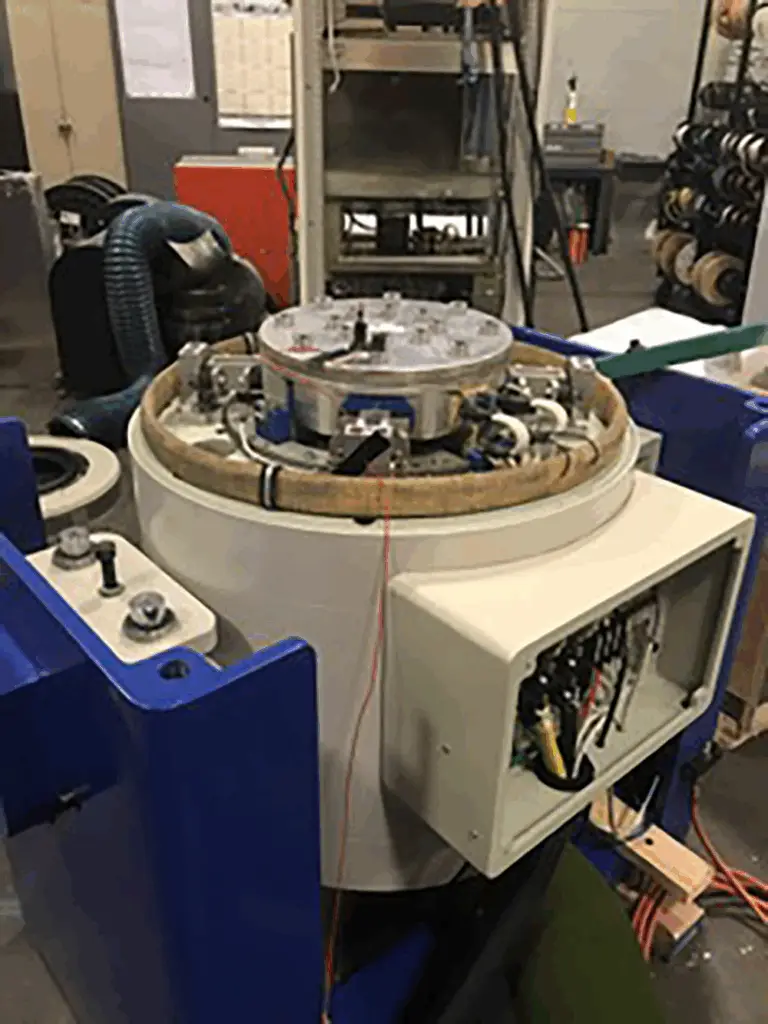

eMpulse Test Systems provides comprehensive refurbishment, maintenance, and repair services for electrodynamic shaker systems—including both traditional electromagnetic and servoelectric configurations. Our experienced engineering team ensures systems are restored to optimal performance, extending service life while reducing unplanned downtime.

eMpulse provides complete refurbishment services for electrodynamic shaker systems, offering a cost-effective alternative to new equipment. Each system includes a one-year warranty and is upgraded with current control technology. Our refurbishment process is designed to restore full functionality and extend service life, supported by a strong record of reliable performance in the field. Customer references are available upon request.

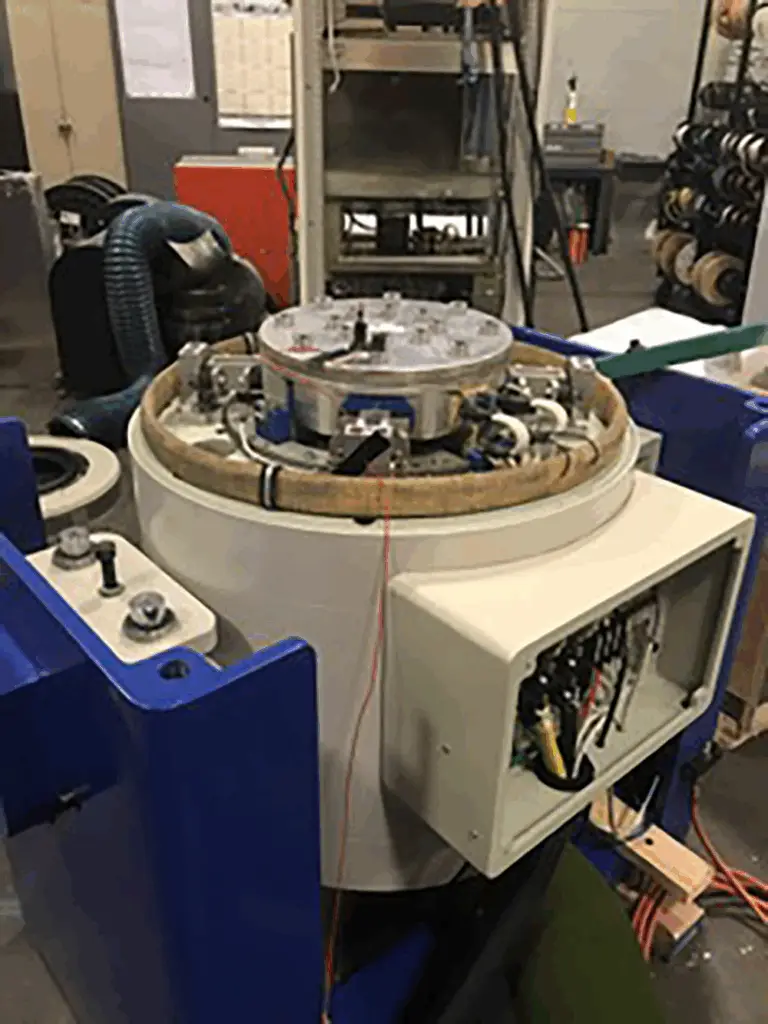

Refurbished systems undergo a full mechanical teardown, with every component disassembled, inspected, and evaluated for wear or damage. Parts are replaced or rebuilt as needed to ensure the system meets original performance specifications.

Mechanical Refurbishment Includes:

- Complete system disassembly and cleaning.

- Inspection of all flexures, shear mounts, and centering systems

- Replacement of bearings, bearing shafts, and worn components

- Armature and field coil inspection

- Terminal and connection integrity checks

- Final assembly, system alignment, and customer-specific repainting

- Operational verification using customer-supplied profiles

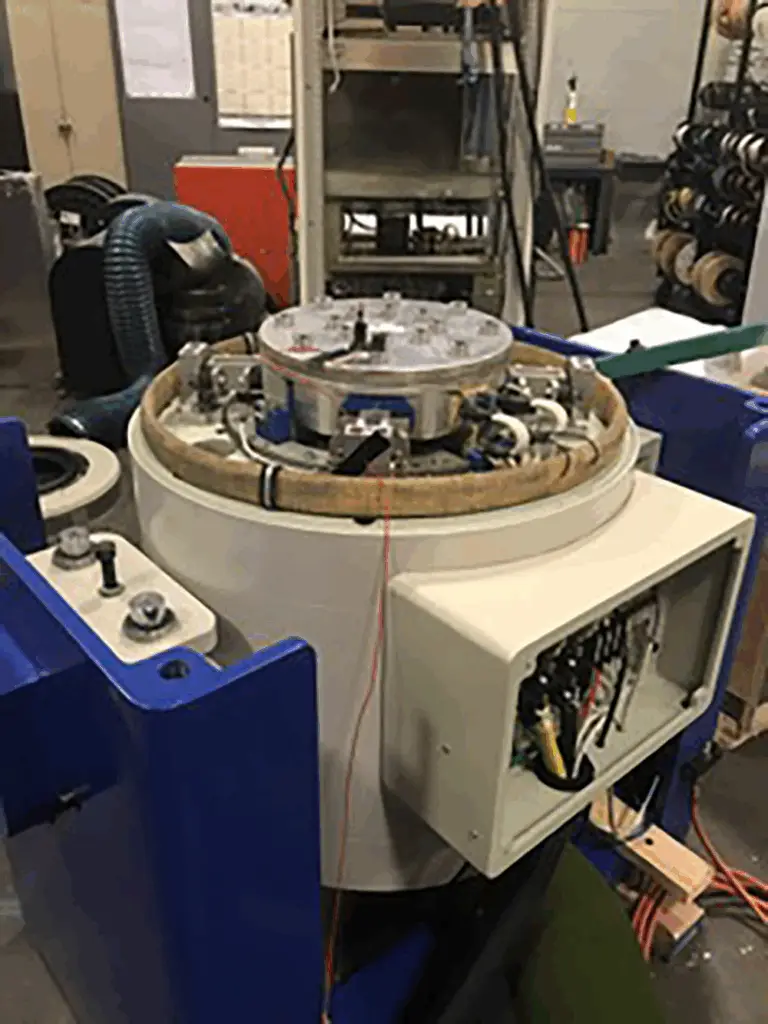

Electrical Diagnostics & Calibration Services:

- Amplifier, field supply, and control electronics inspection and repair

- Fault isolation using calibrated diagnostic tools

- Recalibration of sine, random, and shock profiles

- Fine-tuning for compatibility with specific test protocols

- Verification of safety interlocks and integration with updated amplifier systems

Preventive Maintenance & Emergency Support:

- Scheduled maintenance programs including thermal imaging, alignment checks, and vibration signature analysis

- Fast-response repair services to reduce downtime and restore test capability quickly

Supported Systems

eMpulse supports a wide range of electrodynamic systems, including:

- Vertical-only and vertical-horizontal (V/H) configurations

- Air-cooled and water-cooled systems

- Integrated slip table assemblies

- Amplifier and controller packages

Supported Brands:

- LDS

- Brüel & Kjær

- Unholtz-Dickie

- IMV

- ETS Solutions

- TIRA

- And others

Complete the form to contact us with service requests for ED Shakers.

Fields marked with an asterisk (*) are required.

Refurbishments and Service

eMpulse Test Systems provides comprehensive refurbishment, maintenance, and repair services for electrodynamic shaker systems—including both traditional electromagnetic and servoelectric configurations. Our experienced engineering team ensures systems are restored to optimal performance, extending service life while reducing unplanned downtime.

eMpulse provides complete refurbishment services for electrodynamic shaker systems, offering a cost-effective alternative to new equipment. Each system includes a one-year warranty and is upgraded with current control technology. Our refurbishment process is designed to restore full functionality and extend service life, supported by a strong record of reliable performance in the field. Customer references are available upon request.

Refurbished systems undergo a full mechanical teardown, with every component disassembled, inspected, and evaluated for wear or damage. Parts are replaced or rebuilt as needed to ensure the system meets original performance specifications.

Supported Brands:

- LDS

- Brüel & Kjær

- Unholtz-Dickie

- IMV

- ETS Solutions

- TIRA

- And others

Supported Systems

- Vertical-only and vertical-horizontal (V/H) configurations

- Air-cooled and water-cooled systems

- Integrated slip table assemblies

- Amplifier and controller package

Complete the form to contact us with service requests for ED Shakers.

Fields marked with an asterisk (*) are required.

Refurbishment Process

Mechanical Refurbishment Includes:

- Complete system disassembly and cleaning.

- Inspection of all flexures, shear mounts, and centering systems

- Replacement of bearings, bearing shafts, and worn components

- Armature and field coil inspection

- Terminal and connection integrity checks

- Final assembly, system alignment, and customer-specific repainting

- Operational verification using customer-supplied profiles

Electrical Diagnostics & Calibration Services:

- Amplifier, field supply, and control electronics inspection and repair

- Fault isolation using calibrated diagnostic tools

- Recalibration of sine, random, and shock profiles

- Fine-tuning for compatibility with specific test protocols

- Verification of safety interlocks and integration with updated amplifier systems

Preventive Maintenance & Emergency Support:

- Scheduled maintenance programs include thermal imaging, alignment checks, and vibration signature analysis

- Fast-response repair services to reduce downtime and restore test capability quickly