Heat Exchanger Test Systems

Heat Exchanger Test Systems for Thermal, Pressure and Durability Validation

Precision CNC machined and ground surfaces to 0.0001” tolerances ensure perfect alignment for system longevity. The rigid welded structure provides the stability required for high-force nail penetration testing while maintaining precise nail alignment throughout the test event. Nickel plating surfaces resist long-term corrosion better than zinc, powder-coating, or paint.

- Radiators

- Oil Coolers

- Pumps

- Hoses and Connectors

- Air Induction Systems

- Intake Manifolds

- Refrigerant Heat Exchangers

- Charge Air Coolers / Intercoolers

- Radiator Thermal Cycle Testing

Heat Exchanger Test Systems for Thermal, Pressure, and Durability Validation

With over four decades of experience in supplying advanced test equipment, eMpulse delivers purpose-built heat exchanger test systems designed for repeatable, controlled heat exchanger testing across automotive and industrial applications. We bring specialized expertise in the design and implementation of fluid durability test systems, supporting complex heat exchanger test requirements involving thermal cycling, pressure cycling, and combined load conditions with precision and reliability.

- Radiators

- Oil Coolers

- Pumps

- Hoses and Connectors

- Air Induction Systems

- Intake Manifolds

- Refrigerant Heat Exchangers

- Charge Air Coolers / Intercoolers

- Radiator Thermal Cycle Testing

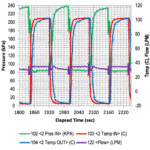

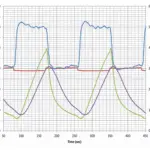

Radiator Thermal Cycle Testing

Mid-flow, closed loop variable ramp rate, thermal cycle

High-flow, closed loop, extended duration ramp rate, thermal cycle

Automotive:

- Temperature: -20 °C to 120 °C

- Temperature transition in 20 seconds

- Flow up to 36 gpm (136 lpm)

- Closed loop pressure – up to 30 psi (200kPa)

Off-Highway:

- Temperature: -10 °C to 110 °C

- Controlled temperature ramping

- Flow up to 100 gpm (378 lpm)

Locomotive:

- Temperature: 10 °C to 90 °C

- Controlled temperature ramping

- Flow up to 200 gpm (756 lpm)

- Integrated Pressure Cycle Capable

Radiator Thermal Cycle Testing

Mid-flow, closed loop variable ramp rate, thermal cycle

High-flow, closed loop, extended duration ramp rate, thermal cycle

Automotive:

- Temperature: -20 °C to 120 °C

- Temperature transition in 20 seconds

- Flow up to 36 gpm (136 lpm)

- Closed loop pressure – up to 30 psi (200kPa)

Off-Highway:

- Temperature: -10 °C to 110 °C

- Controlled temperature ramping

- Flow up to 100 gpm (378 lpm)

Locomotive:

- Temperature: 10 °C to 90 °C

- Controlled temperature ramping

- Flow up to 200 gpm (756 lpm)

- Integrated Pressure Cycle Capable

Additional Heat Exchanger Test Systems

Additional Heat Exchanger Test Systems

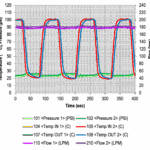

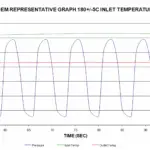

Charge Air Cooler Thermal Cycle Testing

These heat exchanger test systems enable controlled thermal cycling of charge air coolers to evaluate durability under extreme temperature differentials.

- Fully closed-loop controlled system

- Pressure up to 175 kPa

- 200°C ΔT (30°C to 230°C)

- Variable temperature ramp rates

- Flow range from 200 to 2100 kg/hr (±40 kg/hr)

- Up to 6 samples tested

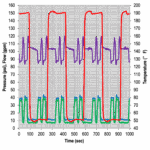

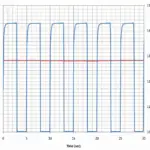

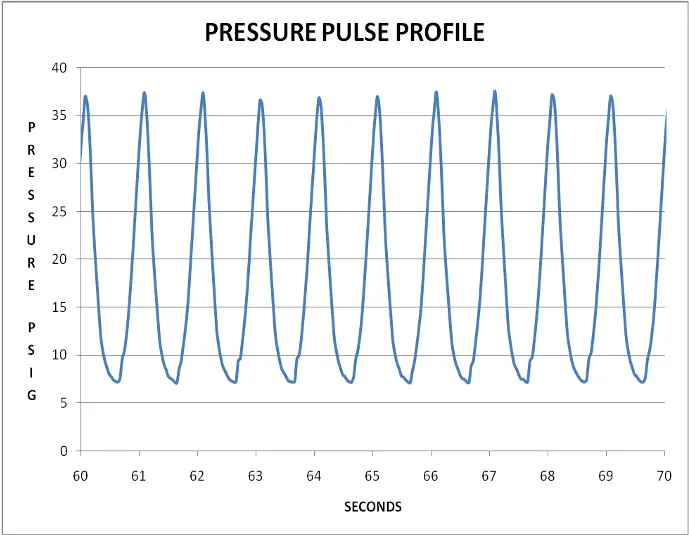

Liquid Pressure Cycle Testing

Liquid-based heat exchanger testing supports multiple pressure cycle profiles to validate component integrity under varied operating conditions.

- Three types of pressure cycle tests

- Test with minimum flow to maintain temperature: 0–60 psig, 140°C

- Static pressure at room or ambient temperature: 0–200 psig

- Steady-state flow: 15 lpm, 0–40 psig, 130°C

- Closed-loop control

- Five systems available

Charge Air Cooler Thermal Cycle Testing

These heat exchanger test systems enable controlled thermal cycling of charge air coolers to evaluate durability under extreme temperature differentials.

- Fully closed-loop controlled system

- Pressure up to 175 kPa

- 200°C ΔT (30°C to 230°C)

- Variable temperature ramp rates

- Flow range from 200 to 2100 kg/hr (±40 kg/hr)

- Up to 6 samples tested

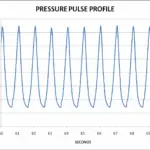

Charge Air Cooler Pressure Cycle Testing

Pressure-based heat exchanger testing is essential for identifying fatigue, leakage, and structural weakness under cyclic loading.

- Air from 0–60 psi ΔP

- Inlet temperatures up to 280°C

- Up to eight samples tested

- Up to eight samples tested

Liquid Pressure Cycle Testing

Liquid-based heat exchanger testing supports multiple pressure cycle profiles to validate component integrity under varied operating conditions.

- Three types of pressure cycle tests

- Test with minimum flow to maintain temperature: 0–60 psig, 140°C

- Static pressure at room or ambient temperature: 0–200 psig

- Steady-state flow: 15 lpm, 0–40 psig, 130°C

- Closed-loop control

- Five systems available

Oil Cooler Pressure Cycle Testing

Oil cooler heat exchanger testing subjects components to high-pressure, high-temperature cycling to ensure durability in demanding lubrication and cooling systems.

- Oil pressure cycled from 0 – 1000+ psi

- Temperatures up to 125°C