Servoelectric Actuation

Servoelectric Actuation

What is servoelectric actuation?

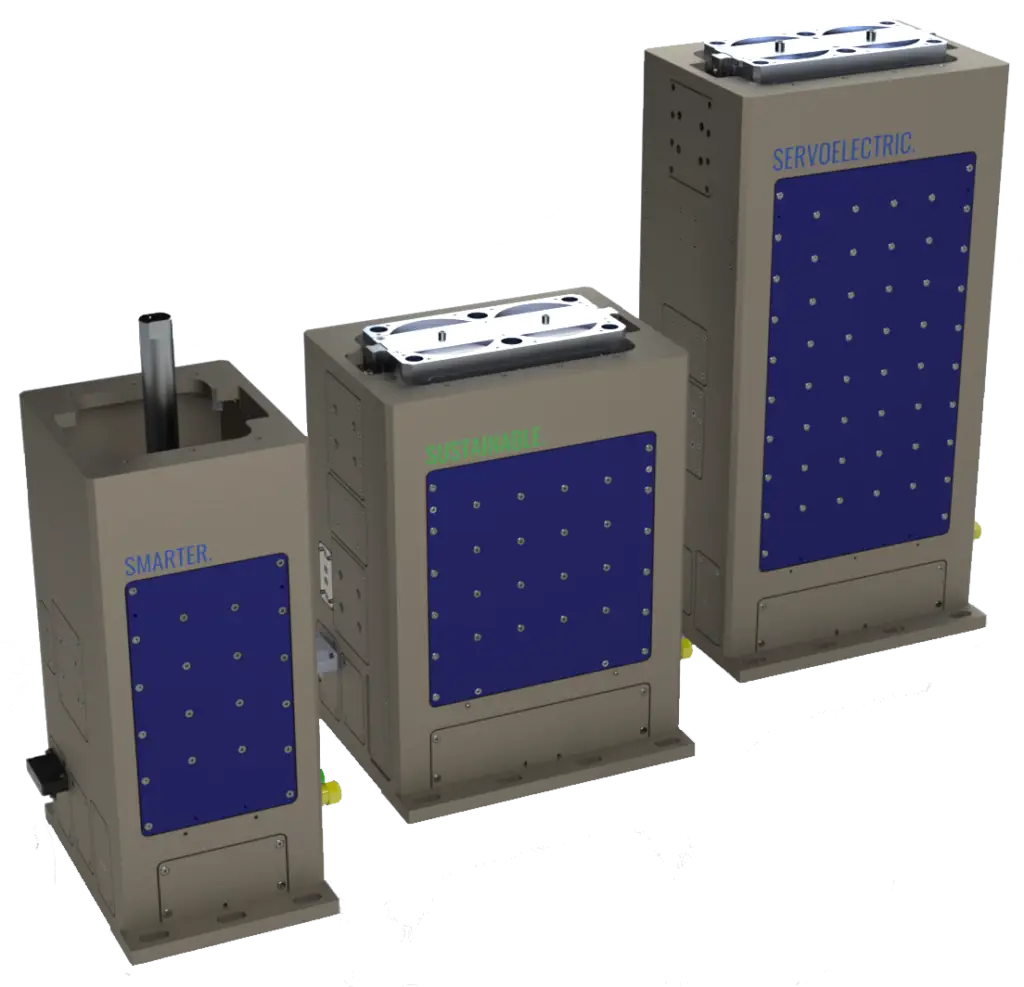

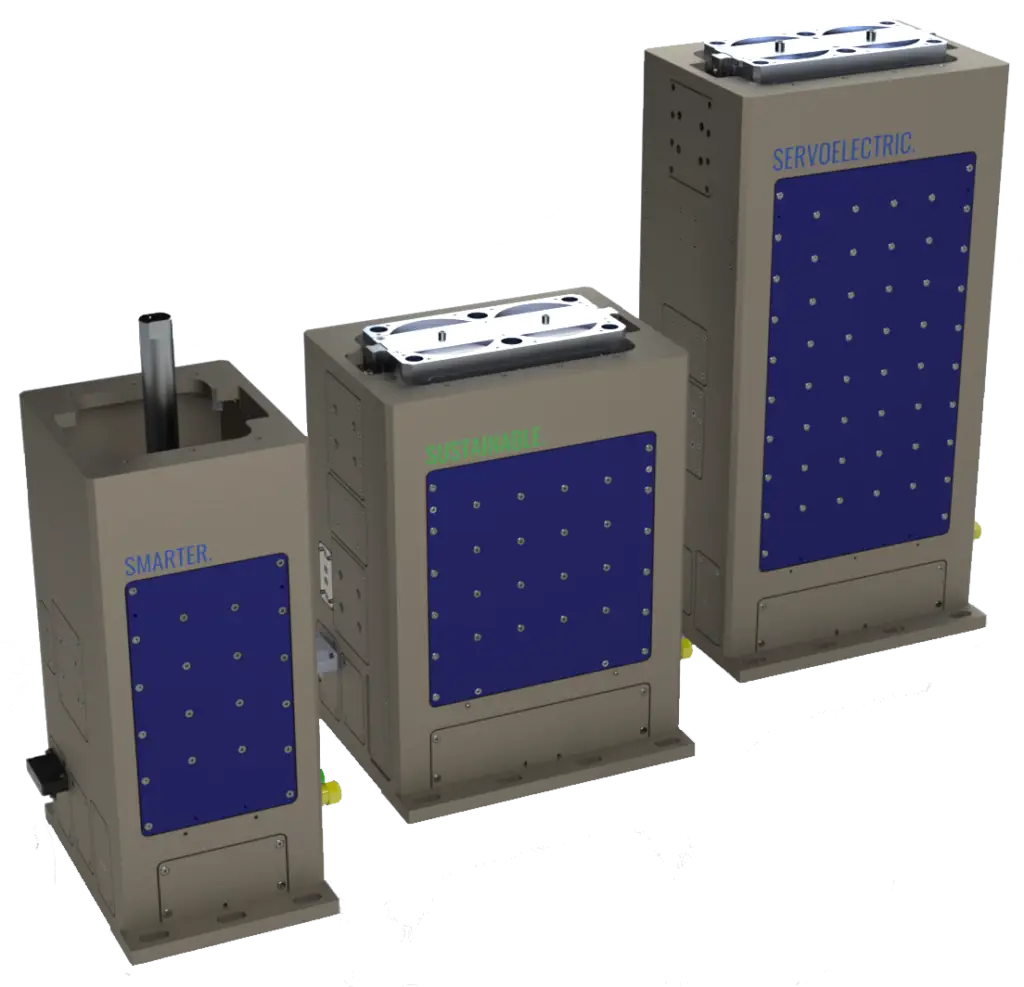

Servoelectric actuation is an advanced motion control technology that uses precision-engineered electric motors and sophisticated feedback systems to generate controlled linear or rotary motion with exceptional accuracy. Unlike traditional hydraulic or pneumatic systems, servoelectric actuators convert electrical energy directly into mechanical movement through sophisticated electromagnetic principles.

By leveraging these technologies, our SEA solutions provide exceptional force control, minimal friction, and repeatable performance that traditional hydraulic or pneumatic systems simply cannot match. This smarter and more sustainable alternative for vibration testing and simulation applications offers significant advantages.

By eliminating fluid-based power transmission, servoelectric actuation represents the next generation of motion control technology, offering unparalleled precision for demanding testing and simulation environments.

- High performance electric motors

- Precision ball screws or linear motion mechanisms

- Advanced digital servo controllers

- Integrated position and force feedback sensors

Servoelectric actuators operate by receiving real-time electrical signals that precisely control motor rotation, which is then translated into linear or rotational mechanical displacement. The integrated feedback systems continuously monitor position, velocity, and force, allowing instantaneous adjustments to maintain exact performance parameters.

What is servoelectric actuation?

Servoelectric actuation is an advanced motion control technology that uses precision-engineered electric motors and sophisticated feedback systems to generate controlled linear or rotary motion with exceptional accuracy. Unlike traditional hydraulic or pneumatic systems, servoelectric actuators convert electrical energy directly into mechanical movement through sophisticated electromagnetic principles.

Servoelectric actuation is an advanced motion control technology that uses precision-engineered electric motors and sophisticated feedback systems to generate controlled linear or rotary motion with exceptional accuracy. Unlike traditional hydraulic or pneumatic systems, servoelectric actuators convert electrical energy directly into mechanical movement through sophisticated electromagnetic principles.

By leveraging these systems, our SEA solutions provide exceptional force control, minimal friction, and repeatable performance that traditional hydraulic or pneumatic systems simply cannot match. This smarter and more sustainable alternative for vibration testing and simulation applications offers significant advantages.

By eliminating fluid-based power transmission, servoelectric actuation represents the next generation of motion control technology, offering unparalleled precision for demanding testing and simulation environments.

- High performance electric motors

- Precision ball screws or linear motion mechanisms

- Advanced digital servo controllers

- Integrated position and force feedback sensors

Servoelectric actuators operate by receiving real-time electrical signals that precisely control motor rotation, which is then translated into linear or rotational mechanical displacement. The integrated feedback systems continuously monitor position, velocity, and force, allowing instantaneous adjustments to maintain exact performance parameters.

- High performance electric motors

- Precision ball screws or linear motion mechanisms

- Advanced digital servo controllers

- Integrated position and force feedback sensors

Servoelectric actuators operate by receiving real-time electrical signals that precisely control motor rotation, which is then translated into linear or rotational mechanical displacement. The integrated feedback systems continuously monitor position, velocity, and force, allowing instantaneous adjustments to maintain exact performance parameters.

Technological Comparison

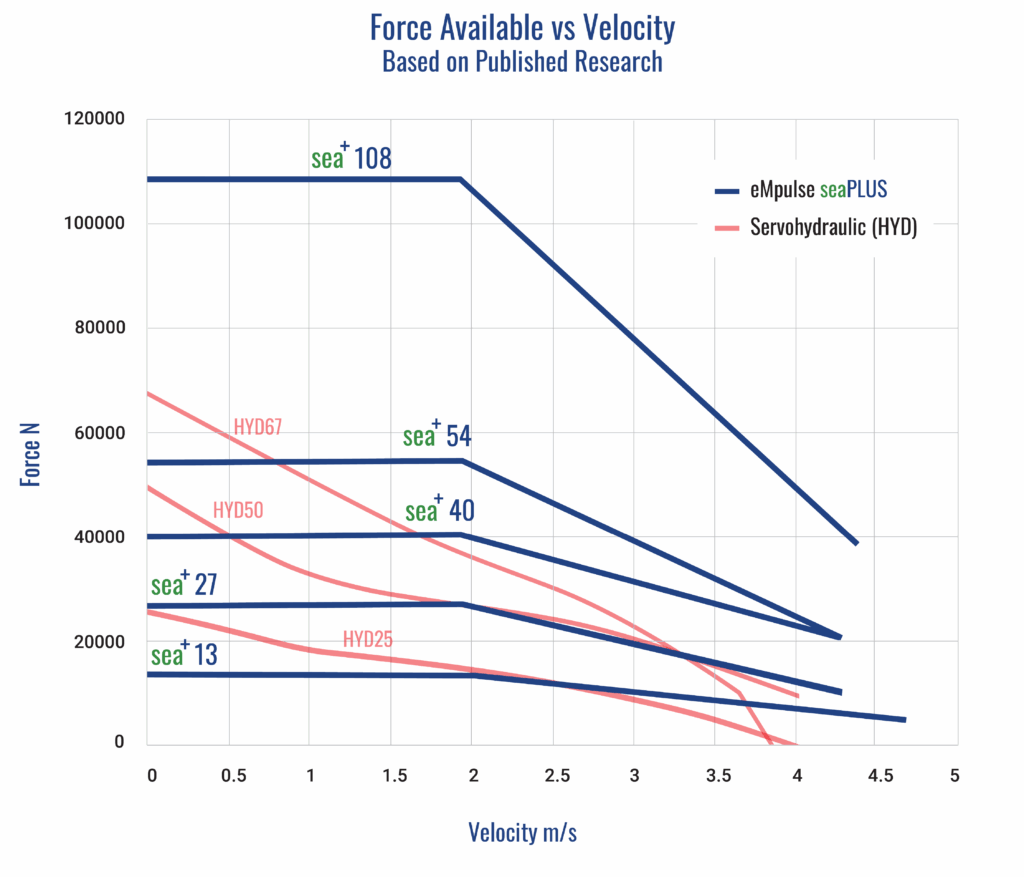

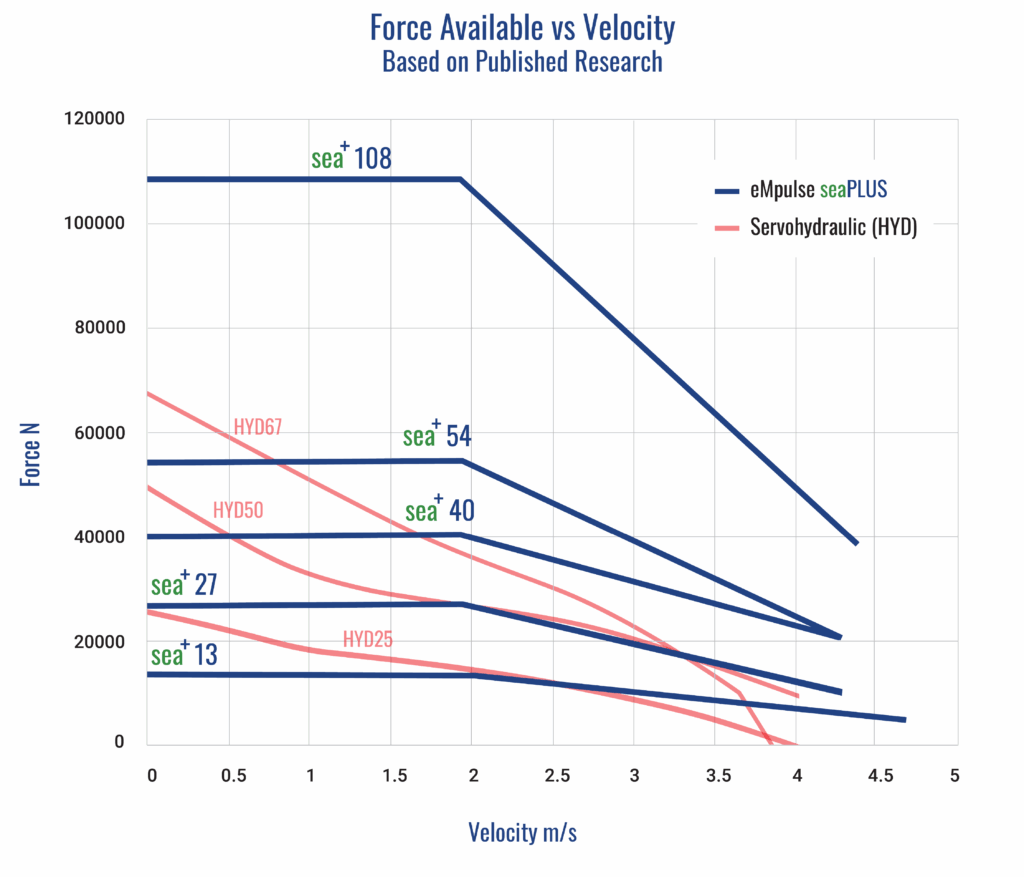

eMpulse servoelectric systems offer a cleaner, quieter, and more efficient alternative to traditional solutions such as servo hydraulic. With fewer maintenance requirements, no risk of leaks, and precise, repeatable performance, our servoelectric approach is built for modern testing environments. By eliminating the complexity of fluid power, eMpulse helps teams reduce downtime, cut energy use, and stay focused on results.

Technological Comparison

eMpulse servoelectric systems offer a cleaner, quieter, and more efficient alternative to traditional solutions. With fewer maintenance requirements, no risk of leaks, and precise, repeatable performance, our servoelectric approach is built for modern testing environments. By eliminating the complexity of fluid power, eMpulse helps teams reduce downtime, cut energy use, and stay focused on results.

Advantages of Servoelectric Actuation

Higher Accuracy and Increased Performance

- High-Resolution Optical Encoder Feedback: At the core of the eMpulse systems are motors equipped with high-resolution optical encoders capable of achieving an impressive resolution of 10nm (0.00001mm). This level of precision ensures accurate measurement and control, enabling detailed analysis of the design under test (DUT) performance under various conditions, and unmatched repeatability.

- Fully Digital Signal Processing: Signals are processed digitally, eliminating noise and signal drift that often plague analog systems. Digital processing enhances reliability, particularly in high-demand testing environments.

- Proven Software Integration: Ensures seamless integration into existing workflows, reducing setup time and improving operational efficiency.

- Real-Time Digital Communication: Components within the system are interconnected via real-time digital communication protocols. This architecture minimizes latency, enabling rapid adjustments and maintaining synchronization across the system.

- High Fidelity and Low Noise: High fidelity 32-bit closed-loop control ensures smooth, accurate motion across all test speeds, without switching valve types or control strategies. The system’s design prioritizes signal integrity. Low noise levels enhance the accuracy of test results, particularly in scenarios requiring fine resolution.

- High Frequency Response: The eMpulse systems support high-frequency response, critical for replicating dynamic conditions in real-world scenarios.

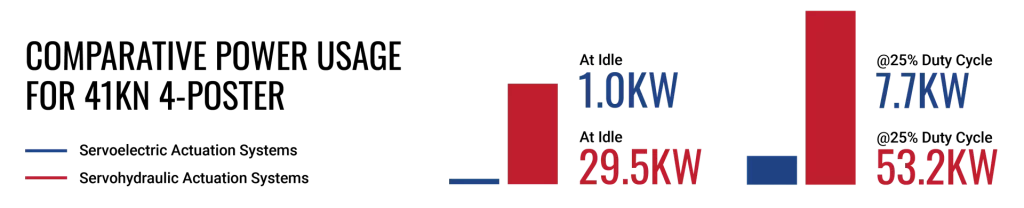

Greater Efficiency

Direct-drive electric motion is more efficient than hydraulics - resulting in only 1/5 of the energy consumption, no fluid handling, reduced maintenance, and a cleaner test environment.

High-Frequency Capability

Motor coherence up to 400 Hz enables test profiles that demand high dynamic response, exceeding the capabilities of servo-hydraulic actuators.

Thermal Management

Increased efficiency in converting electrical to mechanical energy, results in significantly lower heat generation. This improved efficiency reduces the size of the active cooling infrastructure, minimizes thermal loading on components, and contributes to lower overall operational costs.

Solid Welded Construction

Precision CNC machined and ground surfaces to 0.0001” tolerances to ensure perfect alignment for system longevity. Nickel plating surfaces resist long-term corrosion better than zinc, powder-coating or paint.

Improved Reliability

A less complicated actuator assembly resulting in fewer parts yields an increase in reliability and lower maintenance costs.

Integrated Safety Features

These features are built into the control architecture to ensure operator safety and specimen integrity during every test cycle. Every system includes comprehensive safety monitoring:

Reduced Maintenance

Servoelectric actuators are compact, easy to install, and require minimal maintenance, resulting in lower overall system costs.

Improved Troubleshooting

Smart diagnostics capability within the controls can direct operators to the specific hardware causing a fault condition. Remote log-in capability allows eMpulse engineers to aid in troubleshooting anywhere in the world.

Advantages of Servoelectric Actuation

Higher Accuracy and Increased Performance

- High-Resolution Optical Encoder Feedback: At the core of the eMpulse systems are motors equipped with high-resolution optical encoders capable of achieving an impressive resolution of 10nm (0.00001mm). This level of precision ensures accurate measurement and control, enabling detailed analysis of the design under test (DUT) performance under various conditions.

- Fully Digital Signal Processing: Signals are processed digitally, eliminating noise and signal drift that often plague analog systems. Digital processing enhances reliability, particularly in high-demand testing environments.

- Proven Software Integration: Ensures seamless integration into existing workflows, reducing setup time and improving operational efficiency.

- Real-Time Digital Communication: Components within the system are interconnected via real-time digital communication protocols. This architecture minimizes latency, enabling rapid adjustments and maintaining synchronization across the system.

- High Fidelity and Low Noise: High fidelity 32-bit closed-loop control ensures smooth, accurate motion across all test speeds, without switching valve types or control strategies. The system’s design prioritizes signal integrity. Low noise levels enhance the accuracy of test results, particularly in scenarios requiring fine resolution.

- High Frequency Response: The eMpulse systems support high-frequency response, critical for replicating dynamic conditions in real-world scenarios.

Greater Efficiency

Direct-drive electric motion is more efficient than hydraulics - resulting in only 1/5 of the energy consumptoin, no fluid handling, reduced maintenance, and a cleaner test environment.

High-Frequency Capability

Motor coherence up to 400 Hz enables test profiles that demand high dynamic response, exceeding the capabilities of servo-hydraulic actuators.

Thermal Management

Increased efficiency in converting electrical to mechanical energy, results in significantly lower heat generation. This improved efficiency reduces the size of the active cooling infrastructure, minimizes thermal loading on components, and contributes to lower overall operational costs.

Solid Welded Construction

Precision CNC machined and ground surfaces to 0.0001” tolerances to ensure perfect alignment for system longevity. Nickel plating surfaces resist long-term corrosion better than zinc, powder-coating or paint.

Improved Reliability

A less complicated actuator assembly resulting in fewer parts yields an increase in reliability and lower maintenance costs.

Integrated Safety Features

These features are built into the control architecture to ensure operator safety and specimen integrity during every test cycle. Every system includes comprehensive safety monitoring:

Reduced Maintenance

Servoelectric actuators are compact, easy to install, and require minimal maintenance, resulting in lower overall system costs.

Improved Troubleshooting

Smart diagnostics capability within the controls can direct operators to the specific hardware causing a fault condition. Remote log-in capability allows eMpulse engineers to aid in troubleshooting anywhere in the world.

Advantages of Servoelectric Actuation

Higher Accuracy and Increased Performance

- High-Resolution Optical Encoder Feedback: At the core of the eMpulse systems are motors equipped with high-resolution optical encoders capable of achieving an impressive resolution of 10nm (0.00001mm). This level of precision ensures accurate measurement and control, enabling detailed analysis of the design under test(DUT) performance under various conditions.

- Fully Digital Signal Processing: Signals are processed digitally, eliminating noise and signal drift that often plague analog systems. Digital processing enhances reliability, particularly in high-demand testing environments.

- Proven Software Integration: Ensures seamless integration into existing workflows, reducing setup time and improving operational efficiency.

- Real-Time Digital Communication: Components within the system are interconnected via real-time digital communication protocols. This architecture minimizes latency, enabling rapid adjustments and maintaining synchronization across the system.

- High Fidelity and Low Noise: High fidelity 32-bit closed-loop control ensures smooth, accurate motion across all test speeds, without switching valve types or control strategies. The system’s design prioritizes signal integrity. Low noise levels enhance the accuracy of test results, particularly in scenarios requiring fine resolution.

- High Frequency Response: The eMpulse systems support high-frequency response, critical for replicating dynamic conditions in real-world scenarios.

Greater Efficiency

Direct-drive electric motion is more efficient than hydraulics - resulting in only 1/5 of the energy consumption, no fluid handling, reduced maintenance, and a cleaner test environment.

High-Frequency Capability

Motor coherence up to 400 Hz enables test profiles that demand high dynamic response, exceeding the capabilities of servo-hydraulic actuators.

Thermal Management

Increased efficiency in converting electrical to mechanical energy, results in significantly lower heat generation. This improved efficiency reduces the size of the active cooling infrastructure, minimizes thermal loading on components, and contributes to lower overall operational costs.

Solid Welded Construction

Precision CNC machined and ground surfaces to 0.0001” tolerances to ensure perfect alignment for system longevity. Nickel plating surfaces resist long-term corrosion better than zinc, powder-coating or paint.

Improved Reliability

A less complicated actuator assembly resulting in fewer parts yields an increase in reliability and lower maintenance costs.

Integrated Safety Features

These features are built into the control architecture to ensure operator safety and specimen integrity during every test cycle. Every system includes comprehensive safety monitoring:

Reduced Maintenance

Servoelectric actuators are compact, easy to install, and require minimal maintenance, resulting in lower overall system costs.

Improved Troubleshooting

Smart diagnostics capability within the controls can direct operators to the specific hardware causing a fault condition. Remote log-in capability allows eMpulse engineers to aid in troubleshooting anywhere in the world.

Energy Efficiency

eMpulse’s systems are known for their energy efficiency, reliability, and sustainability in industrial testing applications. Integrating SEA technology enhances testing processes and leads to overall operational improvements such as lowered energy use, reduced maintenance, and improved control.

Energy Efficiency

eMpulse’s systems are known for their energy efficiency, reliability, and sustainability in industrial testing applications. Integrating SEA technology enhances testing processes and leads to overall operational improvements such as lowered energy use, reduced maintenance, and improved control.

Energy Efficiency

eMpulse’s systems are known for their energy efficiency, reliability, and sustainability in industrial testing applications. Integrating SEA technology enhances testing processes and leads to overall operational improvements such as lowered energy use, reduced maintenance, and improved control.

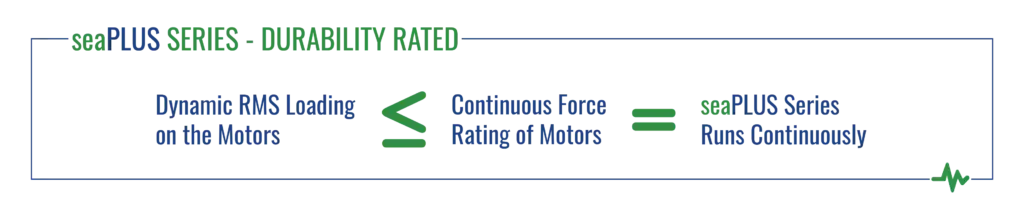

Durability + Servoelectric Actuation

Our servoelectric systems are excellent for durability testing needs. Our systems, using liquid cooled electric motors, can operate with high precision over extended periods, servoelectric actuation offers substantial operational advantages.

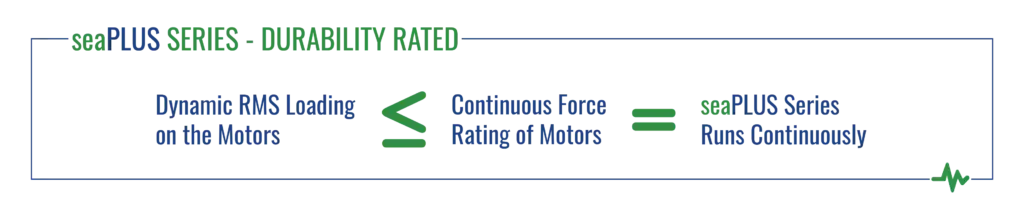

Durability + Servoelectric Actuation

Our servoelectric systems are excellent for durability testing needs. Our systems, using liquid cooled electric motors, can operate with high precision over extended periods, servoelectric actuation offers substantial operational advantages.

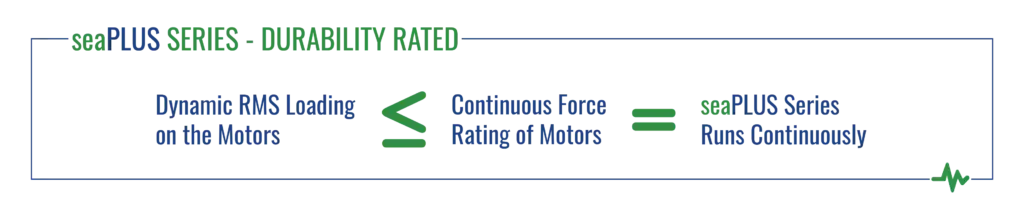

Durability + Servoelectric Actuation

Our servoelectric systems are excellent for durability testing needs. Our systems, using liquid cooled electric motors, can operate with high precision over extended periods, servoelectric actuation offers substantial operational advantages.

eMcontrol Servo Controller

NI CompactRIO based Realtime controls

Off the Shelf Hardware

Partnering with National Instruments, offering a wide range of options, makes the hardware flexible and spare parts available in every corner of the world.

Language Support

Our default language in the User Interface is English, but our software is written to handle any language. Ask eMpulse for a quote to provide the language you prefer.

Flexible Intuitive Software

Our core software handles all the control needs of your application. Add-on software will optimize your user experience and allow you to get the most out of your equipment.

eMcontrol Servo Controller

NI CompactRIO based Realtime controls

Off the Shelf Hardware

Partnering with National Instruments, offering a wide range of options, makes the hardware flexible and spare parts available in every corner of the world.

Language Support

Our default language in the User Interface is English, but our software is written to handle any language. Ask eMpulse for a quote to provide the language you prefer.

Flexible Intuitive Software

Our core software handles all the control needs of your application. Add-on software will optimize your user experience and allow you to get the most out of your equipment.