Battery Crushers

Battery Crushers

Battery Crushers

Our battery crushers are purpose-built battery crush test equipment engineered to meet the rigorous SAE J2464 safety standard for electric vehicle energy storage systems. These systems are essential for ensuring the highest levels of safety and performance in Automotive EV batteries, providing comprehensive and reliable testing solutions for the evolving electric vehicle industry.

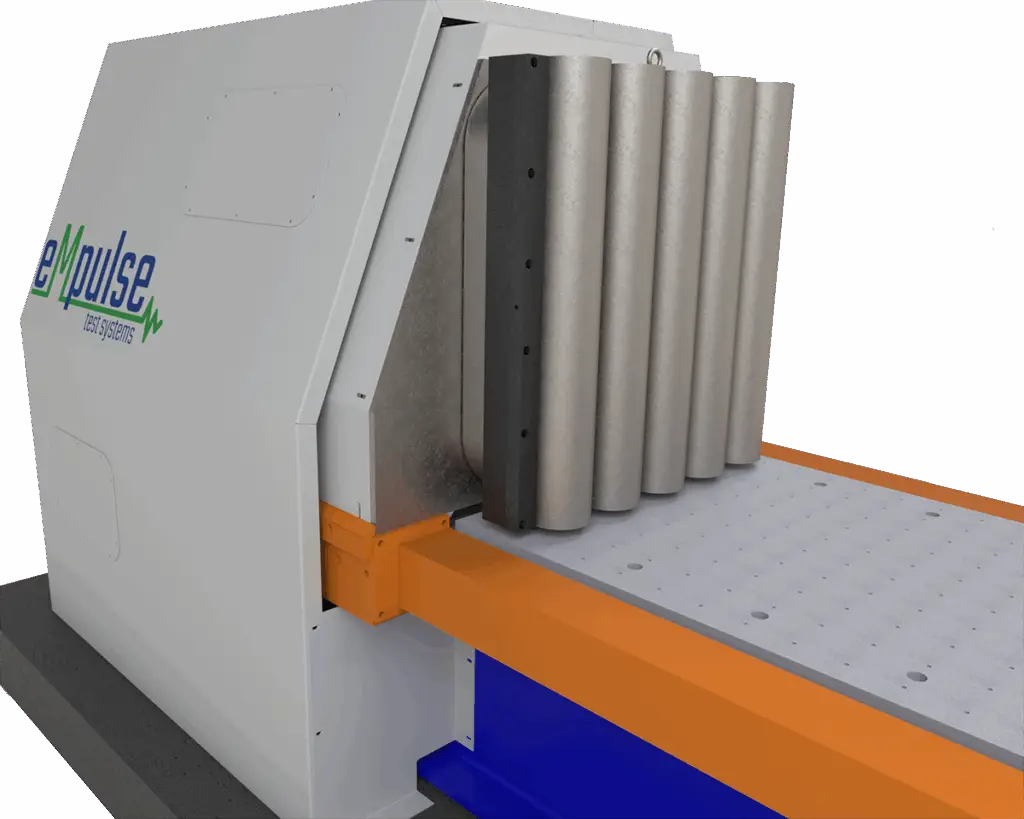

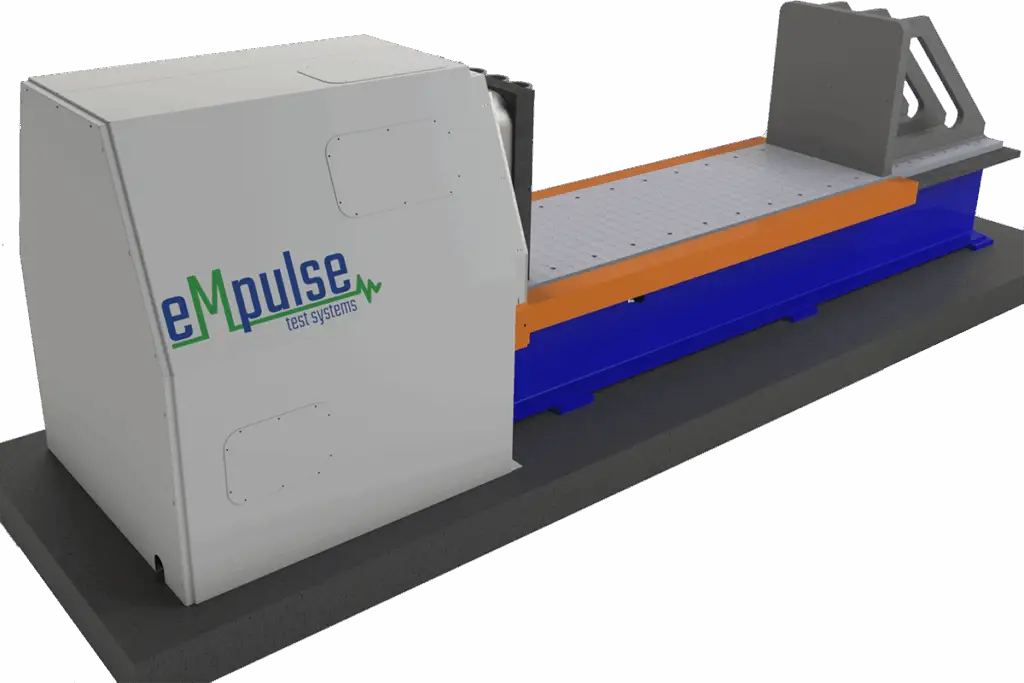

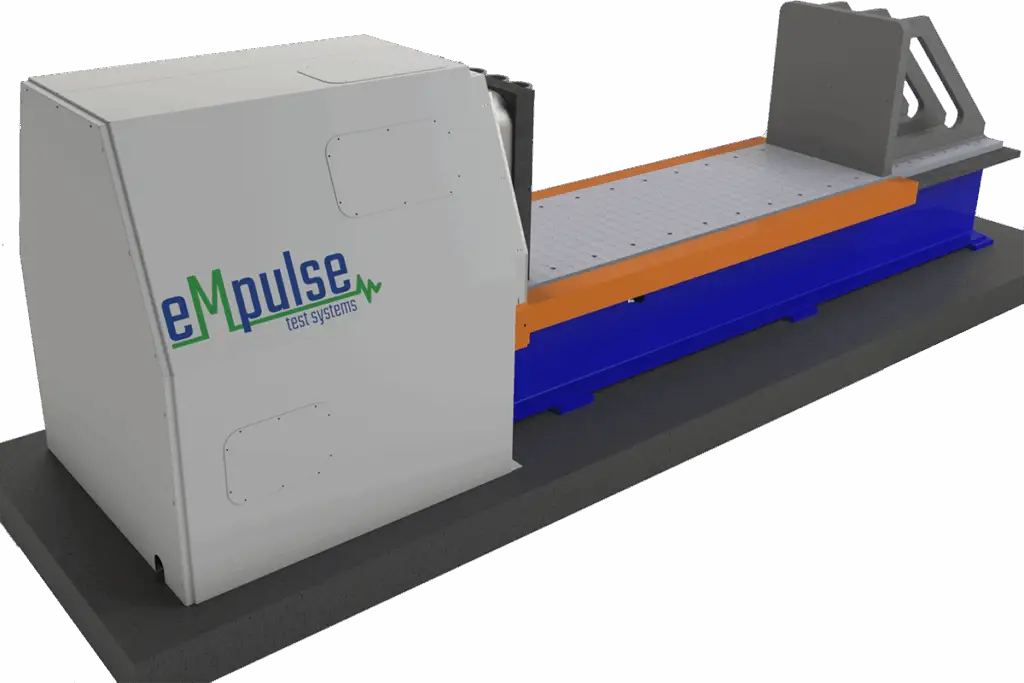

Designed specifically for controlled battery crush testing, each battery crusher applies repeatable force, displacement, and crush speed profiles to evaluate thermal events, internal shorting, and structural failure modes in lithium-ion battery cells, modules, and packs.

Setup in a horizontal configuration with triple reinforced I-Beam rigid base frame. This battery crush test equipment accommodates large-format EV batteries up to 1.5 m in width and 2.75 m in length, making it suitable for full-scale pack-level safety validation. The system delivers precise position, speed, and force control to ensure accurate and repeatable battery crusher test execution.

Battery Crushers

Advantages of Battery Crushers

Comprehensive Data

Data captured during battery crusher testing using servoelectric actuation provides high-resolution insight into force, displacement, and timing throughout the crush event. This information enables real-time monitoring, predictive maintenance, and overall optimization, offering a cleaner and more efficient alternative to hydraulic systems.

Repeatability and Precision Controls

Each battery crusher is engineered for repeatable and precise battery crush testing, maintaining strict crush dimensions, force limits, and calibrated crush speeds. This enables detailed analysis of internal shorting risks, thermal runaway initiation, and heat propagation, ensuring top-tier safety and reliability in EV battery technology. Its calibrated crush speeds allow for detailed analysis of shorting risks and heat propagation, ensuring top-tier safety and reliability in battery technology.

SAE J2464 Compliance

This test equipment is fully compliant with SAE J2464 requirements, including section 4.3.3 Penetration Test (Cell Level or Above) and compliant with section 4.3.6 Crush Test (Cell, Module, or Pack Level), supporting standardized EV battery safety validation programs.

Solid Welded Construction

Precision CNC machined and ground surfaces to 0.0001” tolerances to ensure perfect alignment for system longevity. The rigid welded structure allows the battery crusher to withstand extreme loads generated during high-force battery crush testing, while nickel-plated surfaces resist longterm corrosion better than zinc, powder-coating or paint.

Enhanced Safety

Prioritize safety with advanced features, including real-time monitoring, automatic operation halts for detected risks, and adjustable depth controls. These measures not only protect operators but also create a safer working environment.

Advantages of Battery Crushers

Comprehensive Data

Data captured during battery crusher testing using servoelectric actuation provides high-resolution insight into force, displacement, and timing throughout the crush event. This information enables real-time monitoring, predictive maintenance, and overall optimization, offering a cleaner and more efficient alternative to hydraulic systems.

Repeatability and Precision Controls

Each battery crusher is engineered for repeatable and precise battery crush testing, maintaining strict crush dimensions, force limits, and calibrated crush speeds. This enables detailed analysis of internal shorting risks, thermal runaway initiation, and heat propagation, ensuring top-tier safety and reliability in EV battery technology. Its calibrated crush speeds allow for detailed analysis of shorting risks and heat propagation, ensuring top-tier safety and reliability in battery technology.

SAE J2646 Compliance

This test equipment is fully compliant with SAE J2464 requirements, including section 4.3.3 Penetration Test (Cell Level or Above) and compliant with section 4.3.6 Crush Test (Cell, Module, or Pack Level), supporting standardized EV battery safety validation programs.

Solid Welded Construction

Precision CNC machined and ground surfaces to 0.0001” tolerances to ensure perfect alignment for system longevity. The rigid welded structure allows the battery crusher to withstand extreme loads generated during high-force battery crush testing, while nickel-plated surfaces resist longterm corrosion better than zinc, powder-coating or paint.

Enhanced Safety

Prioritize safety with advanced features, including real-time monitoring, automatic operation halts for detected risks, and adjustable depth controls. These measures not only protect operators but also create a safer working environment.

Advantages of Battery Crushers

Comprehensive Data

Data captured during battery crusher testing using servoelectric actuation provides high-resolution insight into force, displacement, and timing throughout the crush event. This information enables real-time monitoring, predictive maintenance, and overall optimization, offering a cleaner and more efficient alternative to hydraulic systems.

Repeatability and Precision Controls

Each battery crusher is engineered for repeatable and precise battery crush testing, maintaining strict crush dimensions, force limits, and calibrated crush speeds. This enables detailed analysis of internal shorting risks, thermal runaway initiation, and heat propagation, ensuring top-tier safety and reliability in EV battery technology. Its calibrated crush speeds allow for detailed analysis of shorting risks and heat propagation, ensuring top-tier safety and reliability in battery technology.

SAE J2464 Compliance

This test equipment is fully compliant with SAE J2464 requirements, including section 4.3.3 Penetration Test (Cell Level or Above) and compliant with section 4.3.6 Crush Test (Cell, Module, or Pack Level), supporting standardized EV battery safety validation programs.

Solid Welded Construction

Precision CNC machined and ground surfaces to 0.0001” tolerances to ensure perfect alignment for system longevity. The rigid welded structure allows the battery crusher to withstand extreme loads generated during high-force battery crush testing, while nickel-plated surfaces resist longterm corrosion better than zinc, powder-coating or paint.

Enhanced Safety

Prioritize safety with advanced features, including real-time monitoring, automatic operation halts for detected risks, and adjustable depth controls. These measures not only protect operators but also create a safer working environment.